Nanofiber Business

M-TEchX is expanding its business for the mass production of Nanofiber through our unique technology.

Although Nanofiber has a massive market worth over trillions of Japanese yen, commercialization is difficult to achieve due to technical difficulties encountered with conventional mass production methods, as well as the potential hazards such as explosions that may occur during the manufacturing process. However, through our research and development capabilities, we have succeeded in developing cutting edge Nanofiber manufacturing method which is targeted for mass production, as well as the Nanofiber material. Hence it is now possible for us to commercialize Nanofiber.

By capitalizing on this cutting edge Nanotechnology, we take on the challenge to provide solutions to issues arising from transformation in the industries as well as global scale environmental issues.

M-TEchX manufactures and sells [Nanofiber] materials (chemical fiber) that are applicable to products in various industries.

【Features】

- High performance and can be mass produced.

- Easy to commercialize at low cost.

- Wide variety of fiber diameters and characteristics.

- Mass production is possible using low cost raw materials.

We develop Nanofiber production equipment based on our proprietary technologies. We build and operate these equipments, including plant installation design etc.

【Features】

- Mass production is possible.

- Manufacturing technology is safer than conventional ones.

※Equipment for mass production is not for sale.

We conduct research and development as well as the sales of various types of applications, either in-house or through collaborations with other manufacturers, using our newly developed materials.

【Examples of Applicable Products】

- Oil absorbent material.

- Building materials for residential homes, sound absorbent material for vehicles.

- Mask, apparel-related.

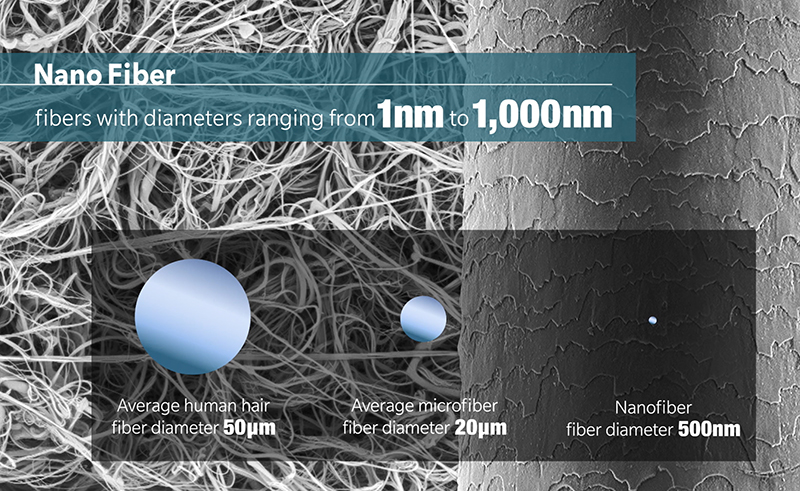

Nanofiber is a fibrous material with a diameter range between 1nm and 1000nm and possesses new properties that are not found in conventional fiber. It is also termed as a super material.

Microfiber / Nano Size Effect

(Air) resistance and pressure loss can be greatly reduced due to the ultra-fine fiber diameter. This will bring innovations to filter products.

Ultra-specific Surface Area Effect

With overwhelmingly large specific surface area per unit mass, many applications of various industries can be created by capitalizing on its strengths such as “High absorption”, “Strong adhesion” and “High molecular recognition”.

Although Nanofiber has a massive market worth over trillions of Japanese yen, commercialization is difficult to achieve due to technical difficulties encountered in conventional mass production methods, as well as potential hazards such as explosions that may occur during the manufacture process. However, through our research and development capabilities,

we have succeeded in developing cutting edge Nanofiber manufacturing method which is targeted for mass production, as well as the Nanofiber material. Hence it is now possible for us to commercialize Nanofiber.

Mass Production Made Possible

It is now possible to mass produce Nanofiber.

Potential Development of Low Cost Nano Products

It is now made possible to produce low cost Nanofiber products derived from our mass production technology.

Magic Fiber (*) is our latest product based on our unique mass production technology.

It is a new material, produced from the world’s top notched nanotechnology, which has huge potential and many great possibilities for the future.

Magic Fiber possesses the same characteristics as Nanofiber produced by conventional manufacturing process, like “Ultra-fine”, “Nano-size Effect” and Ultra-high Specific Area Effect”.

The major advantages of Magic Fiber are its suitability for volume production and the ease of commercialization.

With mass production made possible, high performance Nanofiber products can be manufactured in a stable and consistent way, as well as achieving lower cost advantage.

We have collaboration with Doshisha University, one of Japan’s leading private universities in Kyoto in the development/optimization of new Nanofiber manufacturing equipment, in the acquisition / analysis of various characteristic data and the presentation of our research at academic conferences etc. We worked jointly towards the advancement of development and commercialization of Nanofiber.

Doshisha University/Joint researchers

Faculty of Science and Technology, Doshisha University Professor Toshiki Hirogaki

Research and Development Promotion Organization Associate Professor Wu Wei

Official website of Doshisha University

We introduce nanofiber related patents manufactured by our own technology.

| Title of invention | Patent No | No.of unexamined patent application | Resistration date |

| Nano-fiber production equipment and Nano-fiber production method | 6047786 | 2016-183435 (P2016-183435A) | December 2,2016 |